| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : WITGAIN PCB

Model Number : PCB0027

Certification : UL

Place of Origin : Guangdong China

MOQ : 1 pcs/lot

Price : negotiable

Payment Terms : T/T

Supply Ability : 100k pcs/month

Delivery Time : 10 days

Packaging Details : Vacuum bubble bag packaging

Material : FR4 TG>150

No of layers : 2 Layer

Solder mask colour : Black

Surface technics : ENIG

Min Lind Space&Width : 4/4mil

2 Layer PCB Printed Circuit Board Black Solder Mask Immersion Gold

1 2 Layer FR4 substrate material printed circuit board.

2 ROHS, MSDS, SGS, UL, ISO9001&ISO14001 Certificated.

3 FR4 TG150 material, pcb thickness is 1.2mm.

4 Black solder mask and white silkscreen.

5 35um copper on each layer.

6 PCB size is 250mm*90mm/2pcs.

7 Surface treatment is immersion gold 1u'.

8 Customized pcb, need customer to send us the gerber file or pcb file.

| S1150G | |||||

| Items | Method | Condition | Unit | Typical Value | |

| Tg | IPC-TM-650 2.4.25 | DSC | ℃ | 155 | |

| Td | IPC-TM-650 2.4.24.6 | 5% wt. loss | ℃ | 380 | |

| CTE (Z-axis) | IPC-TM-650 2.4.24 | Before Tg | ppm/℃ | 36 | |

| After Tg | ppm/℃ | 220 | |||

| 50-260℃ | % | 2.8 | |||

| T260 | IPC-TM-650 2.4.24.1 | TMA | min | >60 | |

| T288 | IPC-TM-650 2.4.24.1 | TMA | min | 30 | |

| Thermal Stress | IPC-TM-650 2.4.13.1 | 288℃, solder dip | -- | pass | |

| Volume Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ.cm | 6.4 x 107 | |

| E-24/125 | MΩ.cm | 5.3 x 106 | |||

| Surface Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ | 4.8 x 107 | |

| E-24/125 | MΩ | 2.8 x 106 | |||

| Arc Resistance | IPC-TM-650 2.5.1 | D-48/50+D-4/23 | s | 140 | |

| Dielectric Breakdown | IPC-TM-650 2.5.6 | D-48/50+D-4/23 | kV | 45+kV NB | |

| Dissipation Constant (Dk) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 4.8 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Dissipation Factor (Df) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 0.01 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Peel Strength (1Oz HTE copper foil) | IPC-TM-650 2.4.8 | A | N/mm | — | |

| After thermal Stress 288℃,10s | N/mm | 1.4 | |||

| 125℃ | N/mm | 1.3 | |||

| Flexural Strength | LW | IPC-TM-650 2.4.4 | A | MPa | 600 |

| CW | IPC-TM-650 2.4.4 | A | MPa | 450 | |

| Water Absorption | IPC-TM-650 2.6.2.1 | E-1/105+D-24/23 | % | 0.1 | |

| CTI | IEC60112 | A | Rating | PLC 0 | |

| Flammability | UL94 | C-48/23/50 | Rating | V-0 | |

| E-24/125 | Rating | V-0 | |||

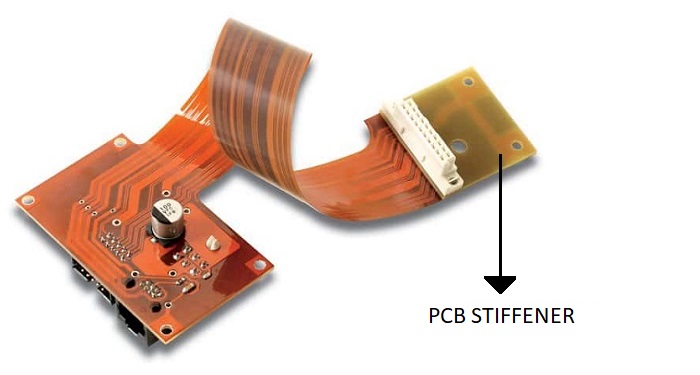

Q1: What is pcb stiffner?

A1: When working with flexible PCBs there are times when we need certain parts of the flexible printed circuit board to be rigid. We do so by adding mechanical support to parts of the PCB. This mechanical support is called a PCB Stiffener.

Flexible PCBs have many advantages like the capability to bend, twist, and fold. However, it is challenging to add/solder components and interconnects to these boards. A PCB Stiffener can be used to make a part of the board more stable/rigid so that it becomes easier to add/solder components or interconnects to the stiffer parts of the board. PCB stiffeners are usually not an integrated part of the PCB. They are only used to provide mechanical support to certain parts of the board.

Other advantages of PCB stiffeners include the reinforcing of solder joints, an increase in abrasion resistance and better handling of the board for automated pick-and-place component placement and soldering.

PCB stiffeners are usually made from FR4, Polyimide or aluminum. The thickness of FR-4 stiffeners varies from 0.003"(0.08 mm) to 0.125" (3.18 mm). The polyimide stiffeners are available with a thickness of 0.005" (125μm), 0.001" (25μm), 0.002" (50μm), and 0.003" (75μm). Polyimide stiffeners are usually a low-cost alternative to FR-4 as they are punched on a die instead of routed with a drill bit. To get better rigidity and heat sinking properties, aluminum stiffeners are used.

There are two main methods to attached PCB Stiffeners to a flexible PCB - Thermal Bonding and Pressure-Sensitive Adhesives (PSA). The properties and differences of each approach have been highlighted in the table below:

| Thermal Bonding | Pressure Sensitive Adhesives (PSA) |

| Stiffeners are attached to the flex PCB by using heat and pressure | Stiffeners are attached with the flex PCB by only using pressure |

| Stronger Bond | Bong not as strong |

| Used in bonding in IPC class 3 product (Military application, Avionics etc.) | Used in bonding in IPC class 2 product (TV, laptops, Consumer electronics etc.) |

| Higher Cost | Lower Cost |

| Will cause significant damage to the circuit while removing from flex circuit. | Usually removed without damaging circuit, if care is taken while removing. |

| Process take more time | Process takes less time |

|

|

ENIG Dual Layer PCB 4mil Laminate Circuit Board Immersion Gold Images |